Tag Archives: Franz

Throwback Thursday #4

This message addressed to the local agent at Franz gives some instructions for his daily work handling waybills for cars in the station and preparing switchlists and other information for trains working there.

While the first two notes about making sure cars billed with “south” destinations went to southbound no. 5 and “north” cars went to northbound no. 6 are rather obvious, the rest is interesting and involves the handling of various un-billed empty cars. An empty gondola is to be sent south to Sault Ste. Marie (Steelton yard) and an empty rack (40′ pulpwood flatcar) held in the yard. The “chip boxes” referenced are likely empty Canadian Pacific 40′ boxcars held for wood chip loading at the Dubreuil Brothers sawmill ten miles to the south of Franz at Dubreuilville. Reliable sources indicate that in the 1960s and early 1970s chips were mainly loaded into standard 40′ boxcars supplied by CP. Empty cars delivered by CP for loading would be stored at Franz and Wanda, the next siding to the south until needed. As the sawmill ordered in cars for loading, the local agent would fill the orders from this pool of empty boxcars. The chips were shipped to the James River Pulp and Paper mill in Marathon on the CP line along the north shore of Lake Superior.

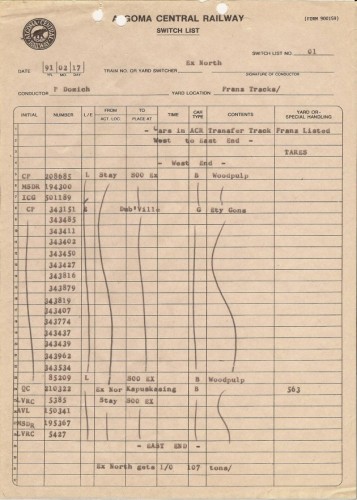

This traffic out of Dubreuilville apparently wound down in the mid 1970s as Dubreuil Brothers shifted to shipping most of their product by truck. In the mid 1980s this traffic came back to the railway and around 1986 there were major track changes and the installation of a new chip loader at Dubreuilville. Chip cars would again be provided by CP, this time in the form of a fleet of dedicated high-sided open top gondolas assigned to the Dubreuilville-Marathon chip service. This 1992 switchlist shows a large cut of empty gondolas for chip loading in the interchange track at Franz:

This lasted through the 1990s until the Dubreuil mill closed in 2007.

Interesting travelogue and a bit more on that service disruption

Over on the Trains magazine site, this interesting two-part travelogue has been posted under one of the editorial sections. The writer traveled from Sudbury to White River on VIA Rail’s RDC (self-propelled Budd Rail Diesel Cars) train service and then intending to ride from White River to Franz and catch the southbound ACR service to Sault Ste. Marie. Unfortunately this happened to be on the day that the passenger train got held up, and he wound up waiting at Franz for no train. Fortunately there was a CN employee that was able to give him a ride out to Hawk Junction in a hi-rail truck. Check out both links, it’s an interesting re-cap:

- Part 1: Budds through the Bush: A sojourn on VIA Rail in northern Ontario

- Part 2: Northern Ontario Adventure: Finding my Way out of Franz

In the second link, he includes this paragraph, which clears up a few other details about the situation that caused the cancellation:

A half hour later (around 1:20 PM), I called again, and the agent made it clear, without divulging details, that she felt it highly unlikely that the ACR train would complete its run that day. I later discovered that a formal complaint was filed with Transport Canada around 10:30 that morning against the crew of the ACR train, alleging that a violation of operating rules had occurred the previous day (the ACR crew was later cleared of any wrongdoing). Once such a complaint is filed, neither crew involved can legally operate a train during a mandatory 48-hour investigation period. That day was only the day after a new operator, Railmark Canada Ltd., had formally taken over the passenger train’s operating contract (replacing CN crews with its own). Since Railmark had not been able to hire any additional crew, it had no way of operating the train until the investigation was complete.

That’s a bit clearer than just “unspecified infraction” that showed up in the media articles which didn’t really have any more information, and I think wraps that all up rather nicely.

Section House Progress

While I was mostly busy with other things over the Christmas and New Year’s period, I’ve been managing to poke away at a couple of projects and have managed to complete another milestone on my Franz section house project, and now I have my first actual project posting of 2015.

The house is now painted, and has shingles applied.

The house was airbrushed white and the trim carefully masked and painted Southern Sylvan Green. I had a setback at this point that rather threatened to ruin the entire project – on one side I sprayed a little too heavily with the green and it leaked and spread under the masking. After venting some frustration (“Model Railroading is Fun”?? – MR’s old tagline) including some choice words that would have disappointed my mother, I tried to recover the project by scraping away some of the green paint, and repainting the side again with white to touch it up and once again masking off the trim and windows and then touching up the green.

I think I managed to not botch it too much the second time around. Phew.

The shingles are a heavy paper product from Rusty Stumps. They are pre-cut for a standard 3-tab shingle pattern and can be ordered with or without an adhesive backing. (Rusty Stumps has several different variations of shingle types available, and different colours are also available. Their dark green will likely come in handy when I build Hawk Junction station…)

You can see above that I have also been working on finishing off the assorted tool and speeder sheds with shingle roofing material as well (I actually completed a few of these over the Christmas season, and applied the last shingles to the section house tonight). Some of these small structures are known to have tarpaper/roll roofing but I’ve managed to source some photos here and there and some of the specific locations I’m intending these for (Franz, Mosher) had shingle roofing on these sheds. Even some of the different section houses had varying roofing and siding treatments, with some of them also having tar paper roofing as well. Franz however, is well documented as having normal black asphalt shingles.

All of the model structures just need a ridge cap applied yet to complete the roofing treatment.

Here we see what the Franz section house would look like in context with its storage shed, although you kind of have to imagine a forest around and behind it, a nearby outhouse, and chances are when I actually build Franz, you’ll end up looking at the back of the house from the aisle.

It’s taken a while, and had it’s bumps along the way, but I’m happy that these structures are really starting to look a bit more like the real ones they represent.

Franz Section House – Porch and Trimming

I’ve had the opportunity to put a little more work into my section house build, and it’s starting to get a lot closer to finished.

Across the front of the structure is a covered porch which extends the full width of the building. According to the standard drawings, the porch extends five and a half feet forward from the structure. To start the porch roof, I built an open framework using scale 4×4 strip for the porch roof. This was a very delicate piece to work with, but holds together fairly strongly once fully assembled with the sheet material for the roof’s surface cemented to the rafters.

After this was all set up, I proceeded to add the fascia trim to all of the roof edges of the structure.

I also built the porch with a sheet of .020″ thick scribed Evergreen styrene sheet material and some .060x.060″ strip framing. Then, to complete the model down to the ground and also hold everything together more rigidly, I added the vertical board cladding all around the bottom supports of the structure. (Some more recent photos at this location show some of this replaced with lattice, but I have a couple of older photos that I’ve saved and archived in my reference folder where this is vertical siding all the way around, so I went with this approach.)

You’ll also notice I’ve added the chimneys for the stoves that heat the structure. To mount the main chimney at the peak of the roof, I filed a notch into the roof itself so that the chimney could be cemented down on a flat surface rather than trying some sort of painful attempt to cut a peaked bevel into the base of the molded plastic chimney which I never would have pulled off cleanly.

The kitchen chimney however had the based filed off at an angle to bevel it to the slope of the roof.