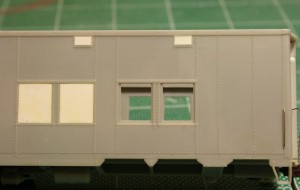

This Sunday I had the advantage of having pretty much the entire day to myself and spent the afternoon masking and painting my modified troop sleeper-cum-baggage car. Earlier in the week, the sides were assembled into the body frame and the body, roof and pipe were separately primered and painted “Aluminum”. Sunday afternoon was spent masking and painting the letterboard stripe (CPR Tuscan/Maroon) and the underbody and sills (flat black).

Once the paint had set and the masking was removed, I installed the window glass (using the original clear parts from the Walthers model for the existing windows and a sheet of clear styrene across the baggage door windows using a bottle of Microscale Kristal Kleer I had on hand (which seems to be more or less basically just regular white glue…?) and then installed the roof. The final bit of assembly involved installing the (previously bent and painted) air? pipe down the roof centreline, gluing it into holes above the end diaphragms, and tacked down at a couple of points to the roof carlines to keep it straight and attached. A small weight was placed on top to hold the pipe down while the glue dried.

With the body painted and assembled, one of the last tasks was to letter the car, which in this case consisted of only adding the car numbers to the four corners of the car using some of the extra digits from the number jumble in the Black Cat ACR passenger set. The railway never did get around to actually applying their name to the maroon stripe on the real car either, so that completes the lettering of this car…

A few final details remain such as stirrup steps below the baggage door and a light (passenger cars usually stayed in pretty good condition) weathering job, but this car is nearly complete!