Pulpwood (that is, raw logs of a grade and size suitable for use at a paper or pulp mill) has been a staple of the ACR’s traffic since it first began construction in 1899. Large amounts of pulpwood were shipped to the paper mill in Sault Ste. Marie and much exported to mills in northern Michigan and Wisconsin as well.

Before I continue, I’d like to give a shout out to Bruce Gignac and Reg Fitzpatrick, former ACR employees who answered a few of my questions here and confirmed some information. Thanks guys!

Newaygo Forest Products

Newaygo Forest Products operated large pulpwood cutting operations north of Hawk Junction with large logging operations and loading spurs in the Mosher and Mead areas. Newaygo also had an additional spur at Trembley, just west of Wawa on the Michipicoten subdivision. Logs from Newaygo spurs were mainly shipped south for export to paper mills at Appleton and Neenah, Wisconsin.

In 1974 Newaygo established a modern sawmill at Mead to produce lumber and woodchips. While this mill was in operation, most of Newaygo’s pulp log traffic was now sent here to be turned into woodchips for export to Wisconsin (more on that later) instead of sending the raw logs south from Mosher. Logs cut around Mead were also processed at the new mill, and a couple of previously listed Newaygo spurs north and south of Mead were removed from the timetable in the late 1970s.

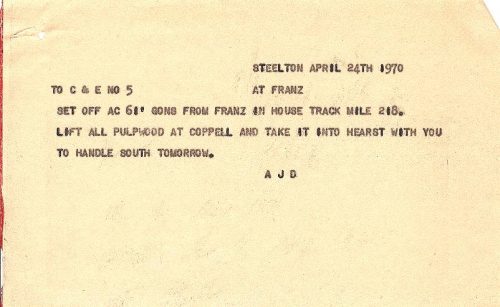

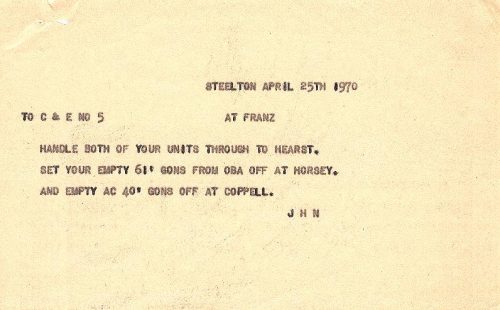

During the 1960s while logs were being loaded for shipment south to the US, most of the export log loading at Mosher was done at the Mosher north spur, at mile 218 (connecting to the house track and siding). After 1974, with logs being shipped north instead to Mead, most loading was done on the Mosher south spur at mile 217.3 just south of Mosher station.

Some logs from Mosher were also sent to the J.D. Levesque plywood mill in Hearst.

Reg Fitzpatrick also mentioned another interesting occasional movement of pulpwood from Mosher in the 1980s. Using privately owned pulpwood cars provided from Kimberly-Clark in Terrace Bay (bearing KCWX reporting marks) some pulpwood was sent from Mosher via Franz to Ontario Paper in Thorold, ON in southern Ontario’s Niagara Penninsula region. Apparently up to 15-20 cars at a time would be loaded for this service, but only three or four times a year (roughly 60 cars/year). Occasionally a rejected load from the paper mill would be sent back to the ACR and these would be sent to Dubreuilville. (Interestingly, some of these same cars were later purchased and assigned to the ACR by Wisconsin Central in the late 1990s.)

Newaygo shut down the mill at Mead and most of their other operations in Algoma County in 1985.

Abitibi Paper (later St. Marys Paper)

Providing pulpwood to the pulp mill established in Sault Ste. Marie in the 1890s by industrialist Francis Clergue (who also developed much of the other early industry in the Sault including the railway, hydro-electric power company and Algoma Steel) was pretty much the reason the line was originally driven into the forests north of the Sault. Originally a component of Clergue’s Consolidated Lake Superior Corporation, in later years the mill was operated by Abitibi Pulp and Paper, and later independently as St. Marys Paper. Its fortunes declining, the mill closed down for good in 2007 and has since been demolished, except for some of the original heritage structures from the late 19th century.

A southbound freight arrives at Steelton yard in the early 1980s with a significant amount of pulpwood, likely for the Abitibi Paper mill. Morgan Turney photo.

Several different spurs owned and operated by St. Marys Paper are listed in the official employee’s timetables, with notable operations at or near Millwood (just north of Agawa siding), Limer and Trembley. This however, doesn’t necessarily tell the whole story, as quite often pulpwood was also loaded at the house track at several different sidings along the line, and this wouldn’t be additionally listed in the timetable. Batchewana, Mekatina, Regent and Frater are a few sidings definitively known to have hosted significant pulpwood loading operations, usually by private contractors but in many cases shipping to St. Marys Paper.

Other

In addition to Newaygo and St. Marys Paper, probably the biggest shippers and receivers of pulpwood on the ACR, several other mills on the ACR also received logs by rail.

In Searchmont there was a veneer mill operated by Weldwood Canada (later G.W. Martin). Log spurs operated by the same company were located at Eton. This mill shut down around 1990.

In Sault Ste. Marie there was a lumber & veneer mill operated by Weyerhauser in the early 1980s. (Originally established in 1948 as Roddis Lumber & Veneer, and sold [by Weyerhaeuser] to G.W. Martin in the mid 1980s, and later to Lajambe Forest Products, Agawa Forest Products (E.B. Eddy) and Domtar, and still operating today as Boniferro Mill Works). This mill likely received logs from a few locations, and there was a Weyerhaeuser spur at Achigan (mile 42) during the early 1980s (spur listed under G.W. Martin in the late 1980s). I’ve seen a number of photos such as the one below with loads of larger logs, mostly shot in or near Sault Ste. Marie. I’m guessing that the Weyerhaeuser mill is a likely destination for these although I honestly don’t know for certain. I’m not sure where these logs are loaded either, but this very nice Dave Beach photo shows that at least some of them come from north of Montreal Falls (mile 92).

The Steelton yard switcher shuffles a cut of cars of logs. Early 1980s photo by Morgan Turney.

After the Wisconsin Central takeover in late 1995 or early 1996 a new oriented strandboard (OSB) mill opened at mile 153 north of Perry siding. Video and photos that I’ve seen do show that logs were shipped here by rail in AC flatcars, but I’m not sure where from. This mill closed sometime around 2007 due to the general decline in the northern Ontario forestry industry in the early 21st century.

The sawmill at Dubreuilville did not general receive much in the way of logs by rail, as their cutting rights were close to their mill and mostly delivered by truck.

Loading pulpwood on the team track behind the freight shed at Hawk Junction, March 1981. Photographer unknown, slide in my collection.

In addition to isolated spurs owned or operated by specific companies as above, there are several smaller logging companies that show as operating their own spurs – these smaller companies would likely have sold their logs to the area mills in Searchmont, the Sault or Michigan. Also as mentioned above in the St. Marys Paper section, a lot of pulpwood was loaded at house tracks at various locations and wouldn’t be reflected in the “Loading Spurs” section in the timetable.

Pulpwood flatcar owned by Besse Forest Products. Besse operated a loading spur beside Steelton Yard in the early 2000s for export pulpwood. At Sault Ste. Marie in August 2004. My photo.

Columbia Forest Products was another company that had a pulpwood loading operation on the ACR’s property behind the Steelton car shops in the late 1990s and early 2000s; Columbia also operated the plywood mill in Hearst from 1995, and presumably these logs loaded in Sault Ste. Marie would have been shipped north over the railway to the mill.

Operations Today

Today the paper mill at Sault Ste. Marie and various forest products mills at Searchmont, Limer, Dubreuilville and Mead are all closed, but there is still some loading of pulpwood for export to Michigan and Wisconsin.

When I rode the tour of the line to Hearst in 2013, I noted active operations at Odena (mile 10), Eton (mile 120) and Langdon (mile 240, just south of Oba). This summer I also heard southbound freight 574 on the radio doing some switching of log spurs at or near Regent siding (mile 89).

Log spurs at Eton, September 30, 2013. My photo.

There’s also some current movements of pulpwood from one of the spurs/sidings (not sure which) on the former ACR to somewhere in Quebec (I’ve not yet been able to determine exactly where these are going). These travel up to Hearst where they are routed over the Ontario Northland into Quebec via Rouyn-Noranda.

Also, across town at the Huron Central yard, pulpwood is loaded for shipment to the Domtar mill at Espanola. While this is not really related to the ACR per se, I’m not sure if logs for this mill were also loaded at locations along the ACR at times as well.