Lumber traffic (excluding stuff like plywood, veneer, etc. – we’ll get to that next time) on the ACR consists primarily of four main sources:

- Weyerhaeuser (later Domtar) at Sault Ste. Marie

- Dubreuil Bros. (later Dubreuil Forest Products) at Dubreuilville

- Newaygo Forest Products at Mead

- bridge traffic from Hearst

Weyerhaeuser/Lajambe/Domtar

This mill, located approximately mile 4 in Sault Ste. Marie, produced hardwood lumber and veneers. Established in 1948 as Roddis Lumber & Veneer, in the early 1980s it was owned and operated by Weyerhaeuser Canada. In the mid 1980s Weyerhaeuser sold the mill to G.W. Martin (which also purchased the former Weldwood of Canada veneer mill at Searchmont near the same time). Later ownership changes saw the mill owned by Lajambe Forest Products and later E.B. Eddy and Domtar, with the mill being last sold by Domtar in 2003 to Boniferro Mill Works, which appears to still operate the facility today.

This mill received logs and shipped out finished product by rail. Although I don’t have photos or records to confirm this, I would presume most of their output to be shipped south for export.

Dubreuil Forest Products

The Dubreuil Brothers Lumber Co. established a sawmill just west of Hawk Junction in 1951, and in 1961 moved their operations up to what is now Dubreuilville and established a company town there. During the late 1960s, Dubreuil Bros. began shipping more of their product by truck to Michigan rather than by rail, and sources indicate that from about 1975 through 1986 Dubreuilville was pretty dead as far as rail shipments were concerned, except for a few carloads a year of fresh railroad ties, as they had the contract to supply the ACR.

In about 1986-87 Dubreuil Forest Products switched back to shipping lumber by rail in a big way; tracks were rebuilt and an additional spur for woodchips installed. A second connection was added to the ACR main turning the spur into a wye that could be switched from either direction and yard limits established around the location to facilitate switching. The lumber loading track was able to hold nearly two dozen 60′ cars.

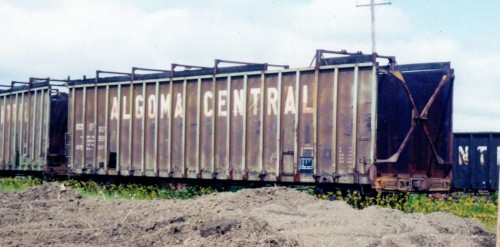

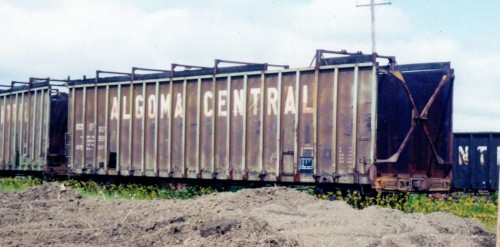

Former woodchip car ACIS 1415 modified as a special lumber car for Dubreuil Forest Products service. Photographed in June 2000 behind the Steelton car shops.

A unique service that the ACR provided at Dubreuilville was using a small fleet of about half a dozen survivors from their former fleet of woodchip gondolas which were modified for lumber service. When switching the mill tracks at Dubreuilville, the ACR would always ensure that one of these was spotted at the end of the track where it would be loaded using a ramp. The loaded cars were delivered to Sault Ste. Marie where Dubreuil used to have a lumber yard adjacent to Steelton yard and unloaded there for transloading onto trucks. Between standard flatcars and these modified chip cars, Dubreuil could load up to a dozen cars per day here.

The Dubreuilville mill closed in 2007, a victim of the general downturn in the Canadian softwood lumber industry at the time.

Newaygo Forest Products

Newaygo Forest Products built their mill at Mead in 1974 to ship out export lumber and woodchips to the US. A couple of sources suggest that a destination for a lot of the lumber produced by Newaygo (and possibly from Dubreuilville as well after Newaygo shut down) was a large modular home builder in Mancelona, Michigan.

The Newaygo mill only lasted in operation until 1984 or 1985.

Bridge Traffic

Additional lumber traffic on the ACR comes from the Ontario Northland (formerly CN) interchange at Hearst. (Today this is the only lumber traffic still operating over the former ACR.)

NOKL 734517 with a Tembec lumber load at Sault Ste. Marie, August 2004.

Significant nearby mills include Lecours Lumber in Calstock (approximately 20 miles west of Hearst), Tembec (former Malette Lumber, former United Sawmills, former Fontaine Lumber) in Hearst and Tembec (former ?) in Kapuskasing. Other lumber comes from a bit farther afield on the ONR and beyond as I’ve also seen lumber from Scierie Landrienne, EACOM (former Domtar mills) and Resolute Forest Products (formerly Abitibi-Bowater) mills in northern Quebec heading towards Hearst via CN and Ontario Northland.

CBRY 1527 with a load of lumber from Scierie Landrienne of Landrienne, QC at Cochrane, ON in a train departing for Kapuskasing and Hearst. July 2013.

Note: I have printable graphics to make your own wrapped lumber loads for most of the companies mentioned above on my Lumber Loads page.