So I was just routinely checking in here recently, and I realized it’s been well over a year since I posted anything new on this blog. Where does all the time go?!

I thought I should at least throw some sort of update here on this blog. While I haven’t really completed any projects worth writing about on this AC blog, I’ve remained active with various things in the hobby, although non-ACR projects have been dominating my workbench over the last while, but I supposed I can highlight some of the things I’ve been doing. After all, this is my blog site, and I can post whatever I like, although the focus here will always remain on the ACR.

As you can see from my last post here about AC covered coil steel gondolas, I’ve gotten into some 3D design and printing. While it’s certainly providing an avenue for certain ACR projects, my major current projects have been CPR related projects for the club layout, not my personal ACR.

A lot of people who know me – particularly in person, but I’ve mentioned it here once or twice as well – will be aware that I’ve been involved with the Waterloo Region Model Railway Club for many years. If you don’t know the club, we are trying to model the actual location and operations of the Canadian Pacific Railway around Sudbury, Ontario as it existed during the decade of the 1970s. This means a lot of custom structures, but also some unique rolling stock and equipment that was used in the area.

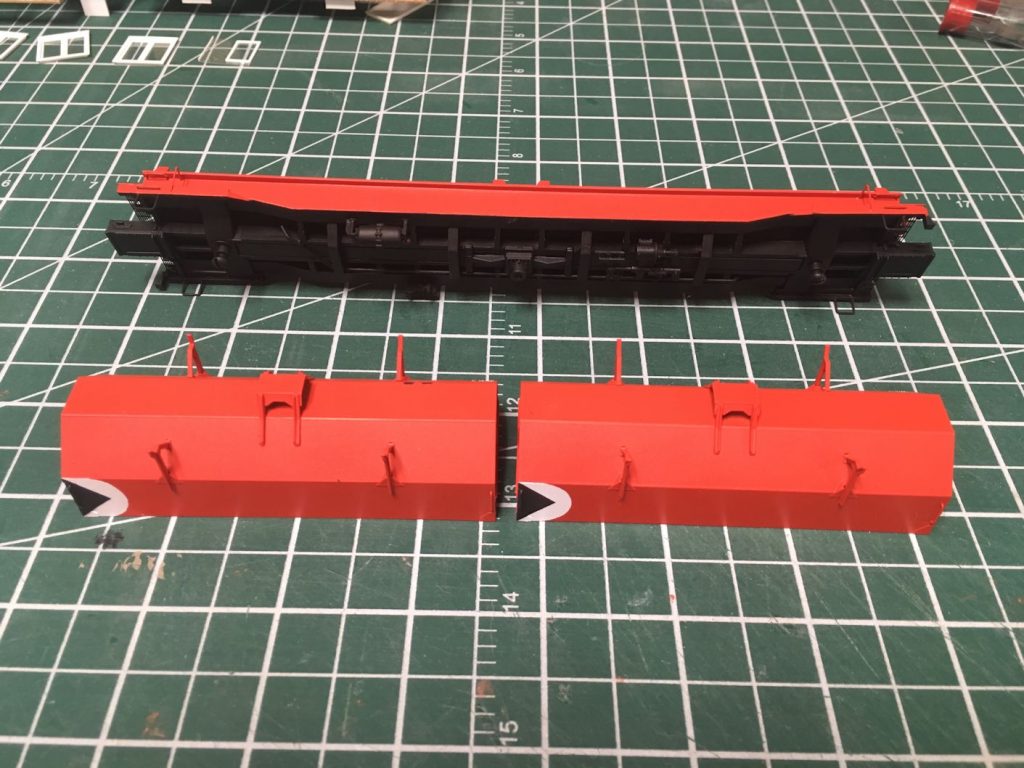

In this vein, I’ve been working on a pair of large, long-term projects for the CPR Sudbury Division. One of the biggest and most important things that I saw 3D printing would solve is the unique fleet of 26′ drop-bottom gondolas that were used for hauling nickel ore from local mines to the INCO smelter near Sudbury.

These cars were unique to this area and its operations, so other than grossly inaccurate stand-ins painted in CP colours, these are cars that will never be done as mass-produced models. There was one version of these cars that was made as a resin kit many years ago by Sylvan Scale Models, but it’s a tricky build and only one of roughly half a dozen different variants of these cars that was in service.

I’ve been working on a massive project over the last three years to design, print, and build an entire fleet of ore cars for service on the club layout. I’ve completed four distinct model designs (including a replacement for the Sylvan car, which builds up much easier than the old kit, which during this design process I also found rides a bit high with an underframe that’s a bit too tall).

As of last summer, we have 35 completed cars allowing our first nickel mine on the layout to actually open for service, running loaded and empty trains back and forth to Sudbury yard. Many more cars still need to be built to service two more mines and a quartz quarry, which aren’t built yet, but construction expansion on the layout is steaming ahead and while the project scope is large enough to take a few more years, being able to run to these locations is at least visible on the horizon.

I’ve done some detailed posting on this project in a thread on the Model Railroad Hobbyist forum, which you can read here.

My other large project which has taken almost three years of off-and-on work is the passenger station and attached division office building at Sudbury.

Both of these structures are significant large structures that are a unique signature of the prototype location. Both structures together are nearly four real feet in length.

The station (which still stands today, and is still used by VIA Rail for their Sudbury-White River local RDC service) was modeled by 3D printing the walls in sections. The roof is constructed from sheet styrene, but everything below the roof line, as well as the dormer windows, was printed.

The second building, which housed the administrative offices for the Sudbury Division and baggage-express functions (which later moved into the station after the old station restaurant closed in the mid 1970s), was built as a conventional styrene scratchbuild, however I printed all my own custom doors and windows (over a hundred, in about half a dozen different varieties). (The prototype structure was abandoned after the Sudbury Division was merged with the Schreiber Division and administrative functions moved to Schreiber, and torn down around 2000.)

Both model structures aren’t quite finished, and need some more finishing work, but they’re getting close. I’m hoping to at least have the station finished 100% early this fall, and get as much done on the administration building as I can and actually complete this project over the fall/winter.

I’ve also posted a bit more detail about these buildings and this construction project in an MRH forum thread.

You can see all of the above projects at the fall open house of the WRMRC on October 18, 2025.

My other little sideline isn’t really taking a lot of actual modeling work at the moment, and may seem like it comes completely out of left field, unless you know a bit more about my personal life.

Two years ago I got married, and my spouse is from Mexico. Over the last year we’ve made a pair of trips to Mexico to her home town to visit her family. Her home is in Orizaba, Veracruz, which happens to be located on a busy line operated by Ferrosur running between Mexico City and Gulf of Mexico ports of Veracruz and Coatzalcoalcos. Apart from spending time getting to know my new family and seeing where my wife is from, we also managed to catch some railway action while we were there.

This has inspired a bit of an interest in Mexican railways, and I’ve been diving into learning more about the Ferrosur line, and I’ve been picking up a small representative collection of equipment, starting with a pair of beautifully rendered ScaleTrains Ferromex AC4400CWs. And then a small collection of various rolling stock to build one or two representative train consists similar to what runs on this line.

It’s definitely a very different sort of flavour to either the ACR or the CN line where I live, with different equipment and operations. Mountain railroading in this district leads to some pretty wild usage of DPU, and rock guards over the windows on all the locomotives used down there adds a unique character, and I kinda dig the Ferromex red/green/white colour scheme (although it’s being actively replaced by a newer red and grey scheme on the prototype).

I’ve also been posting in more detail on this topic on another MRH forum thread, if you’re interested.

Not to worry though, I have no current plans to abandon the Algoma Central, although when I have the layout space to actually build the ultimate layout, I might dedicate some space to include an area dedicated to small layout or “operating diorama” based on a Mexican theme. I still have lots of different ACR projects in various forms of “in progress” – some more actively than others – including working on 3D design and printing some AC wooden cabooses.

These are mostly done and ready for assembly and finishing; a half dozen bodies are all laid out in my paint shop next to another batch of those CP ore gondolas. Between balancing various projects such as wanting to finish up the Sudbury station project this fall/winter, and general other life priorities, hopefully I can also get these painted this winter.

Anyways, there’s plenty of other projects either on the workbench or shelf as well, so there’s definitely more to come, even if I’m not sure when exactly.