As the large Algoma Steel plant in Sault Ste. Marie is arguably the primary industry on the Algoma Central Railway in any era, steel traffic forms a major part of the tonnage carried by the railway, and included in that is “coil” steel (as far as I know, the only major steel product not produced by the Algoma mill is wire). Thin sheet steel is wound into coils that are shipped out to manufacturing plants across the continent to be turned into all manner of steel products.

To transport this valuable cargo by rail, the rail industry developed cars with V-shaped wood-lined loading troughs to transport the coils without damaging them. Some of these cars were flatcars or gondolas with the loading troughs added, but by the 1960s several builders were producing various specially designed cars for coil steel service.

Note – There seems to be a bit of a gray area in whether or not to class these special cars as flats or gondolas – indeed today most of the modern equivalents are now pretty universally considered as gons (“GBSR” AAR designation), and while many identical cars were also classed as “GBSR” by their owning roads, the cars I’m about to discuss were classed (at least initially) as “FMS” by both CN and CP.

A major builder and innovator of this type of design – a coil car with lengthwise loading troughs, removable hoods, tracks for moveable load restraint bars, and cushioned underframe to protect the contents – was Evans Products which built hundreds of these cars for most of the major American railways. A minority builder was Canada’s Napanee Industries (NI) of Napanee, ON which built a total of 75 cars in 1967 following the Evans design (probably under license for the Canadian market) for Canadian National (25 cars – CN 190200-190224) and Canadian Pacific (50 cars – CP 313500-313549).

A model representing the Evans Products coil car was and is produced in HO by Walthers. (A very similar US Railway Equipment car is produced by Intermountain (formerly Red Caboose tooling) but the body is different and has a straight sill). The Walthers car is somewhat of an older model, dating back to when Walthers actually sold their cars as kits (and I picked up a 3-pack of kits quite a number of years ago that lived for a [long] time on my shelf), but with a few upgrades these can still make respectable models, and an easy kitbash to one of the Napanee cars.

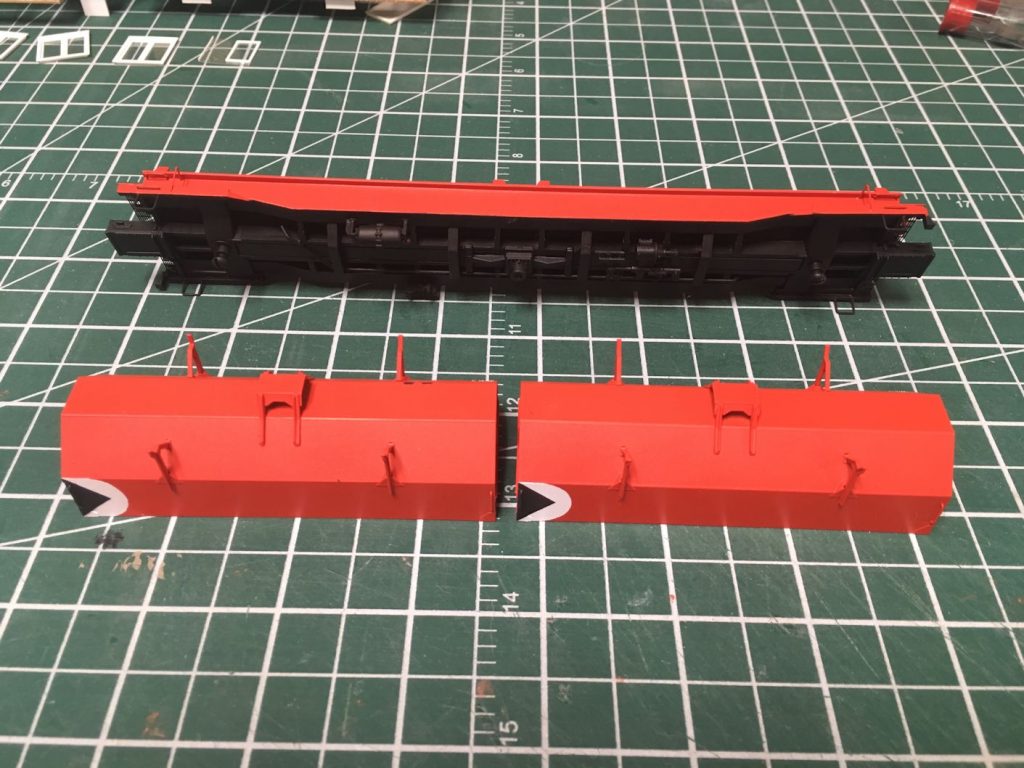

The first thing to do to the Walthers model is to cut away the original walkway and throw it out. Not only is this part rather thick and crude by today’s standards, the Napanee cars did not have the full-length side walkways featured on the model. I also carved off moulded grab irons and stirrup steps to replace them with finer wire parts.

To cover the holes left by the walkway supports and seam between the body halves, rather then trying to fill and sand body putty along the length of the body between the upper and lower flanges (or to be more honest, trying and giving up), I simply laminated 0.005″ styrene sheet cut to fit to the car side to get a smooth result.

Since the NI cars didn’t have full walkways, the removable hoods did not have lengthwise handrails on them either, which the Wathers model has. This is a pretty simple matter to carve off the handrail supports and sand them smooth. At the same time I took the opportunity to replace the corner grabs on the hoods with wire. Otherwise the hoods are essentially “stock” with all the kit parts, although I did scratchbuild matching hoods using the kit part as a pattern for a fourth car that had come with rounded hoods…

Wire grabs were mounted to the body, and step handrails also added from brass wire. The walkway grating on the ends of the cars was added using Plano etched material. The final modification is a small triangle of styrene strip angling from the side sill outboard of the trucks to the bottom of the main body, and a small loop of brass wire representing a protective guard around the brake control valve on the side.

Painting and lettering the cars is where things get a little interesting, as there’s no specific decal sets available. I built and painted two cars for CP, one in original black and one in red (2 more cars for CN are still in the paint shop).

The red CP car was painted and lettered following a prototype photo of

freshly painted CP 313500 on pg. 99 of “Canadian Pacific Color Guide to Freight and Passenger Equipment: Volume 2” by John Riddell and published by Morning Sun Books. This shows a car in a 1970s repaint.

The car and hoods were sprayed with Rapido ProtoPaint “CP Action Red”, and then masked off to paint the underside of the car and the draft gear black. Also the multimarks on the hoods were custom masked and painted as no decal was exactly the right size. The rest of the lettering was cobbled primarily from a Highball gondola set (although almost any CP Rail freight car decal would work as a source) and some Microscale consolidated stencils. The prototype was a 1979 repaint, so no ACI label is present on this car. Numbers and data were painstakingly put together with a magnifying visor.

The black car consumed no less than three sets of Black Cat decals – 2 sets of a gondola with script lettering (CPR340998) for the hood logos and end reporting marks, and a skeleton “stake” flatcar (CPR305560) set for the correct size reporting marks and numbers. This provided ample data to work with. Incidental decals such as ACI labels and consolidated stencils were added from Highball and Microscale sets. As these are 100-ton cars, U-1 wheel dots do not apply.

Perhaps if I were doing a larger set of these cars in the future I might commission a custom set of specific decals, but I was able to piece enough of it together from existing sets.

The cars still need to be sealed and weathered, but for now the paint and lettering work is for the most part completed on these two CP cars. Hopefully the CN fleet will have its pair completed soon as well.

Chris–

Nice work. How is the quality of the Highball decals, is it as good as Microscale, etc.? Thanks!

The artwork is good on these CP sets, the decal film is maybe a bit thicker and covers the whole sheet, so you have to trim around the edges of the piece of lettering you’re putting on. It’s not like Microscale decals where the film is only around each lettering element and has a thin edge. Some of their sets are silk-screened and some may still be printed I believe. Some of their multi-colour sets show the colour dithering of printed sets where dots of different colour ink try to replicate a color that doesn’t perfectly exist in the ink colours of the printer. Not as much of an issue with all black&white sets though.

They have a number of useful CN and CP sets though, and while Microscale has better printing and decal film sometimes, they aren’t necessarily perfect in terms of accuracy either. There are some MicroScale sets with known issues, and some that are pretty good.

Anyway, there’s some good sets there that can make a good result. I’ve done a number of cars now with HighBall sets including the red car shown here, the Expo86 boxcar, CPAA boxcars, and some CN and CP flatcars.

Good job, looks exactly like the cars that used to roll by my place outside of Sudbury on the old Algoma Eastern.