Like every railway, especially those with extensive trackage through remote areas, the Algoma Central rostered a number of bunk cars to use as crew cabins for work crews working on construction or maintenance projects. Many of these cars are customized and home built for specific needs, usually from retired passenger or freight equipment.

The Algoma Central had a number of such cars converted from their old 36′ boxcars originally built in the early 20th century. There appeared to be a number of these in the 10600-10620 range, with a few others scattered elsewhere in the 10000 series work car numbering. A few of these cars were still in service in the early 1980s although starting to be replaced by pre-fabricated bunk units on flatcars (some of which reused the same numbers), and hoistman’s bunk car 10607 was even still in service in the late 1990s at Steelton yard.

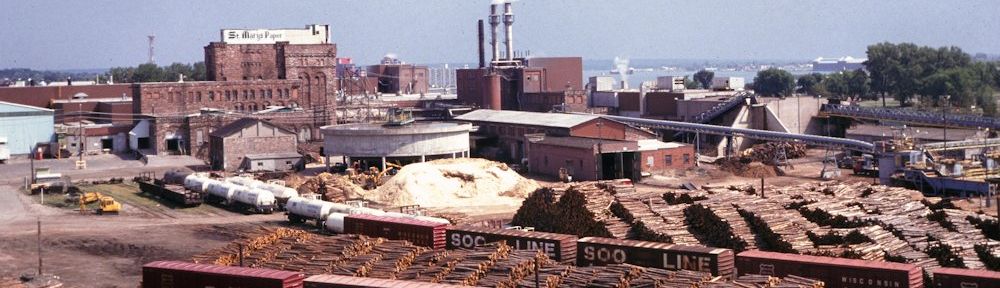

Engineman’s bunk car AC 10608 (above, Ted Ellis photo September 24, 1983) is a good example of the typical configuration of the ACR’s bunk car conversions from the old 36′ boxcars; although from the photos I’ve collected of about 4 or 5 different examples of these cars each one is slightly different from each other in the specific details.

Since I’ve been working on a few crane support cars, I’ve also wanted to have that old hoistman’s bunk car (AC 10607) to match up with the crane equipment set (also, that particular car was repainted in a VERY eye-catching bright yellow in the early 1980s). And if I was going to build one, I was going to at least build a second one.

I actually started these around Christmas, but during January and February I basically did absolutely no modelling as I was working on some home improvement projects. However with some of the work out of the way, lately I’ve been able to dive into this project again and make some progress on this pair of bodies.

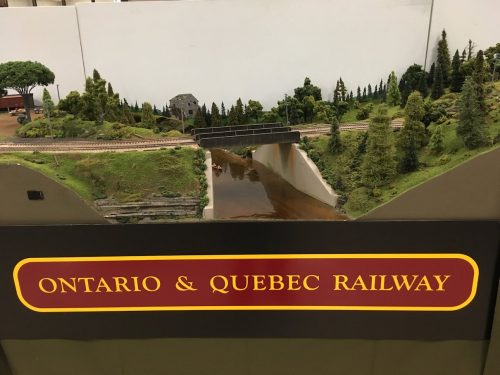

(Left/rear AC 10608 Engineman’s bunk, right/front AC 10607 Hoistman’s bunk)

Each of these two cars are based off of specific prototype photos to match the subtly different details of the cars. (In this case, primarily the end doors on 10607, and differences in ladder details (still to come). Otherwise, the side door and window arrangements on these particular two cars are virtually identical, although other cars had some variations.)

The bodies are fairly straightforward, being built from .040″ scribed styrene sheet. The roofs so far are plain styrene sheet with some internal bracing to maintain the proper shape along the length of the car with some scale 1×8 for the fascia strip along the top of the body at the eaves.

The windows were definitely the most involved and time-consuming part of the project so far. Not having anything that would match both the small windows and larger windows by the doors (I probably could have used some Tichy windows for the smaller ones but nothing for the larger windows) I scratchbuilt all the windows entirely from styrene strip for a consistent look. The single small window shown above is 12 individual pieces of styrene strip including the window sashes and outer frame.

After cutting a scale 24″x24″ opening for the window, the outside of the window was trimmed with scale 1×4″ strip (with a piece of scale 2×3″ for the thicker horizontal sill). The inner frame (sash) of the window was made up of individual .030″x.030″ strips and the window mullions were painstakingly assembled by three pieces of .020x.020″ strip carefully cut and filed to fit exactly in the opening. (An exercise in patience and precision if there ever was one.)

This completes some of the major work on the body however. There is some additional detailing to do, and the doors need to be fashioned and all the ladders/grab irons added to complete the body details and then the roof and underframe will need to be completed yet. I’m looking forward to getting these a bit more detailed and sitting on trucks. I think some of these cars will come together into an interesting looking collection of old cars for a work train at Hawk Junction.