These two interesting gondola cars are support cars that would be paired with one of the railway’s light diesel hoist to carry buckets and other attachments and supplies for the crane.

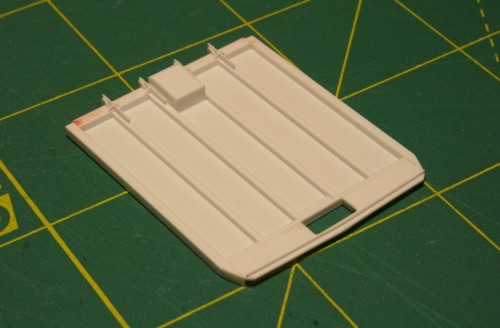

The above car, AC 10588, is a boom car; it carries crane supplies and a clamshell bucket, and would be coupled directly to the crane while in transit, with the crane’s boom positioned and tied down over this car. Notice how the corners of the car have been cut off at an angle to allow the crane boom to swing over the car. AC 10587 has been identified as an almost identical car.

The second car below, AC 10591, is labelled simply as a bucket car. Loaded with no less than four different clamshell buckets, it also features a storage area at the close end for related supplies. The yellow car coupled at the far end is bunk car AC 10607, which was assigned as a crane operator’s sleeping car.

Both of these two cars are also rebuilt from older Algoma Central gondolas from the series AC 4601-4803 or 4804-4850, which were (re)built by the AC’s car shops in 1946-1948 from older 40′ flatcar underframes.

Both photos courtesy of Blair Smith.