(This post is a continuation of a previous post describing my recent visit to ride the Tour of the Line over the Algoma Central Railway.)

At dawn on Tuesday morning, we got up, had our complimentary continental breakfast at the hotel and walked back to the “station” to catch our train back to Sault Ste. Marie.

As we arrived were our train was ready for boarding, there was an Ontario Northland GP38-2 parked on the ladder which appeared to be blocking things for the CN C44-9CW which had arrived some time earlier off of train 571. (This was one of the two engines seen switching at Hawk Junction the day before on train 573. No trace of the second engine was seen this day, so it must have returned to Sault Ste. Marie on a 574.)

After we boarded the train and waited to get rolling, the Ontario Northland began switching the yard tracks and the CN unit was moved out of the way onto side track next to the main, seen in the foreground of the above image. Leaving Hearst we could see that all of the yard tracks had been stub-ended on the west end, except for the first track which served as the siding/runaround.

At Mead there was this office building and a maintenance garage; this was once the site of a large sawmill, but that operation closed down in the mid 1980s. All traces of the mill itself are gone except for a large cleared area, but these two buildings and a portion of the south end of the spur into the mill area are still intact (and the switch to the spur is still in place). Clearly this location must have still been used for some time afterwards to load logs and pulpwood, even though the sawmill was gone. Satellite images of the area shows extensive signs of logging operations in the area.

At Oba and Franz we again crossed the CN and CP main lines. At Oba there were quite a few cars in the old ACR yard tracks, which had been entirely empty the day before. A number of these I recognized as havening been seen at Hawk Junction the previous day.

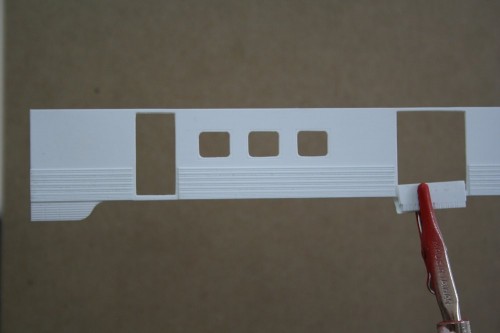

At Langdon, the first siding south of Oba (but clearly used now only as a log spur and not a passing siding) several new empty pulpwood flatcars had been added to the number of cars that had been there the previous day. For an interesting observation, note in the above photo how the switches to the old house track have been removed, but actually the siding track between them removed, so now the siding routes through the old house track. This sort of thing could also be seen at a couple of other locations.

And at Franz, there were a number of cars in the siding which blocked a good view of some of the structures on the west side of the tracks, so I wasn’t really able to get the good overview shot of the location (but fortunately I was able to shoot those buildings from the vestibule the day before when they were not blocked by cars, and I have establishing shots saved from others). Clearly train 571 had had a busy trip from Hawk Junction to Hearst. On our part, we stopped no less than half a dozen times at various locations (along the entire trip) to pick or drop off campers, and by the time we returned to Sault Ste. Marie our little one-coach train was actually relatively full.

And of course I would be remiss in not sharing at least one shot of the famous trestles across the bays of Oba Lake just south of the old Mosher siding and about 15-20 miles north of Franz. The bridge in the photo above is one of the shorter bridges which are both original timber trestles. These bridges are referred to as the “floating bridges.” When they were built, construction crews driving the pilings never did get them resting on solid bedrock, and the bridges essentially float in the mud and silt. The conductor was mentioning this to some of the other passengers while we were still approaching the bridges and remarked that from the ground you can actually see the bridge deflect several inches when a train passes over it! Both bridges have a severe 15 MPH speed retriction. The longest of the three bridges is almost 1200′ long and has at some point been replaced by a modernized version with steel pilings (you could see the old wooden pilings for the original bridge alongside – the water levels were high so these were just below the surface of the water – and also the causeway approaches were wider and showed signs of the realignment) and was not so severely restricted.

After passing through a much emptier Hawk Junction once more, we met the day’s northbound freight 573 at Perry siding. Today the train was short – just 8 cars.

And of course Agawa Canyon is scenic from any angle. Roughly halfway between Eton and Canyon, the valley abruptly narrows from a wide valley to a narrow gorge before widening again through the rest of the canyon. The above photo is taken just after passing through the narrowest point of the Canyon.

Climbing out of the canyon, our train made good time, screaming through the curves between Canyon and Frater. No really, the amount of flange squeal was pretty amazing. Particularly when you’re in the open shooting out the side window of the coach vestibule!

I’ll end this post with one final shot of the train passing through typical (for the south end) rocky terrain just north of Montreal Falls. It’s a long journey but it was enjoyable, and a very relaxed way to travel by rail, with a very different flavour to travelling on VIA or Amtrak!